Zhejiang Dehong Carbon Fiber Composite Materials Co., Ltd. is a pioneering company specializing in high-performance carbon-carbon composite materials. With a focus on innovation and quality, Dehong has established itself as a leader in providing advanced materials for a wide array of industrial applications. Among its diverse range of products, the company offers specialized solutions for the solar PV thermal field, a rapidly expanding sector that demands exceptional materials capable of withstanding extreme conditions. Dehong's offerings, such as Carbon Carbon Support Rings, Carbon Carbon Crucible Holders, and Single Crystal Furnace Heaters, are engineered to meet the stringent requirements of modern solar energy technologies.

The primary function of Dehong’s products in the solar PV thermal field is to enhance the performance and efficiency of solar energy systems. Carbon Carbon Support Rings, Carbon Carbon Support Rods, and Graphitized Carbon Plates are integral components used in high-temperature environments, where they provide structural support, thermal management, and enhanced durability. These materials are particularly important in photovoltaic manufacturing processes, such as the production of solar cells, where precise thermal control is crucial.

Products like Carbon Carbon Crucible Holders and Furnace Base Trays are vital for holding and supporting molten silicon during the crystallization process in solar cell manufacturing. The single crystal furnace heaters are used to precisely control temperature in the formation of silicon crystals, essential for producing high-efficiency solar cells. Additionally, Long Fiber Carbon Plates and Rigid Insulation Felt play critical roles in insulating and thermally stabilizing the manufacturing equipment, ensuring reliable operation in harsh, high-temperature conditions.

Dehong’s carbon-carbon composite products stand out due to their remarkable properties, making them the go-to solution for demanding thermal applications. These materials boast excellent thermal conductivity, which ensures effective heat dissipation, critical in preventing overheating during solar panel production. Their high-temperature resistance allows them to maintain stability and performance even in furnace environments exceeding 2000°C.

Another key feature is their exceptional mechanical strength, which ensures the structural integrity of components during high-stress applications. The carbon-carbon materials are also highly resistant to thermal shock, ensuring longevity and reducing the need for frequent replacements in high-demand industries like solar PV manufacturing. These materials are also lightweight, making them easier to handle and install, while also improving the overall energy efficiency of the system.

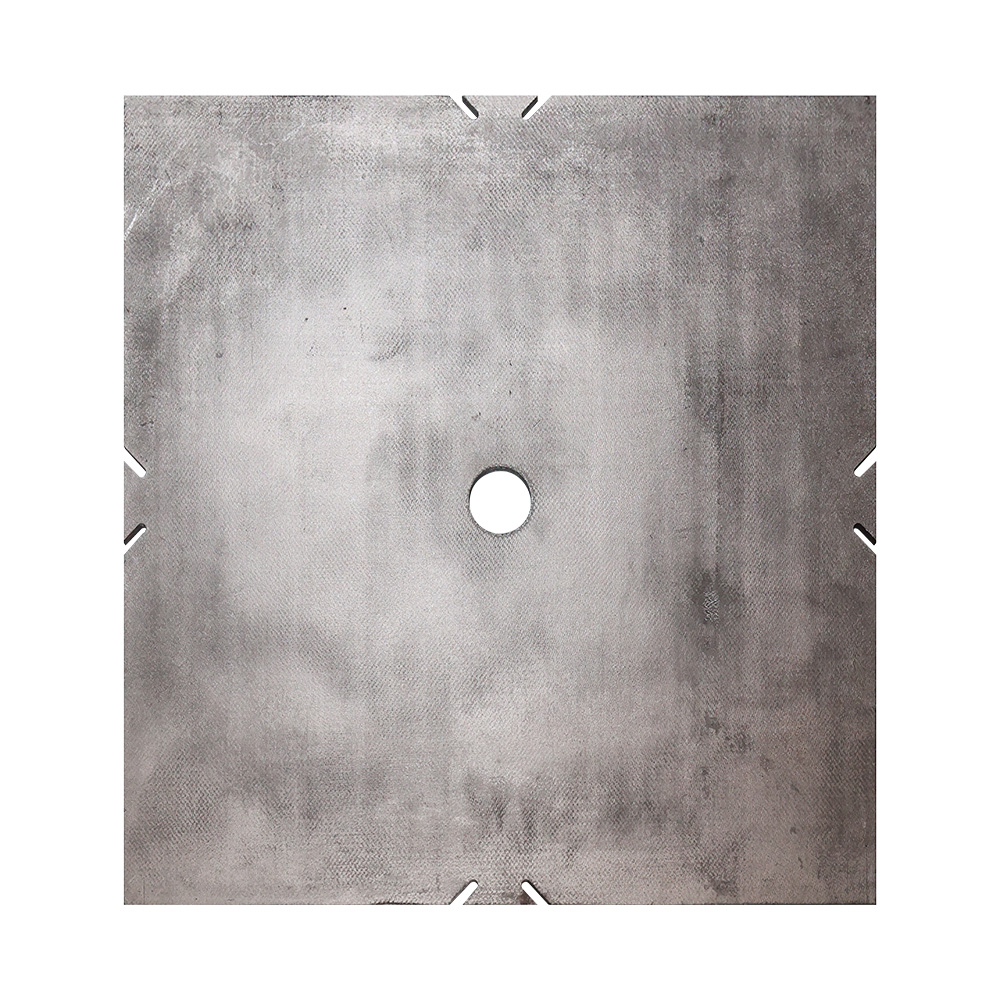

Carbon Carbon Support Rings and Rods: These products are designed for use in high-temperature environments, with a maximum operating temperature of up to 2500°C. Made from advanced carbon-carbon composites, they provide excellent dimensional stability under thermal cycling conditions.

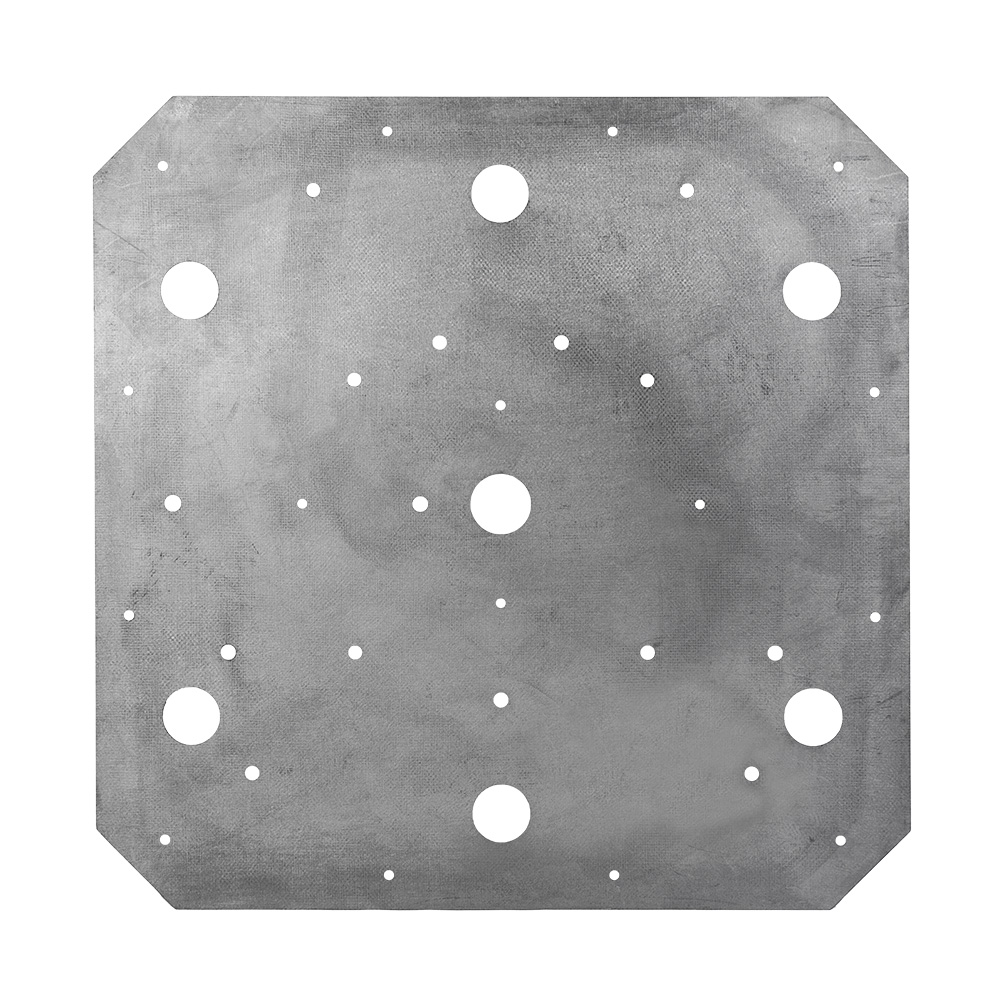

Carbon Carbon Crucible Holder: Capable of withstanding temperatures above 2500°C, these holders are resistant to oxidation and thermal degradation, ensuring they remain reliable in high-heat applications.

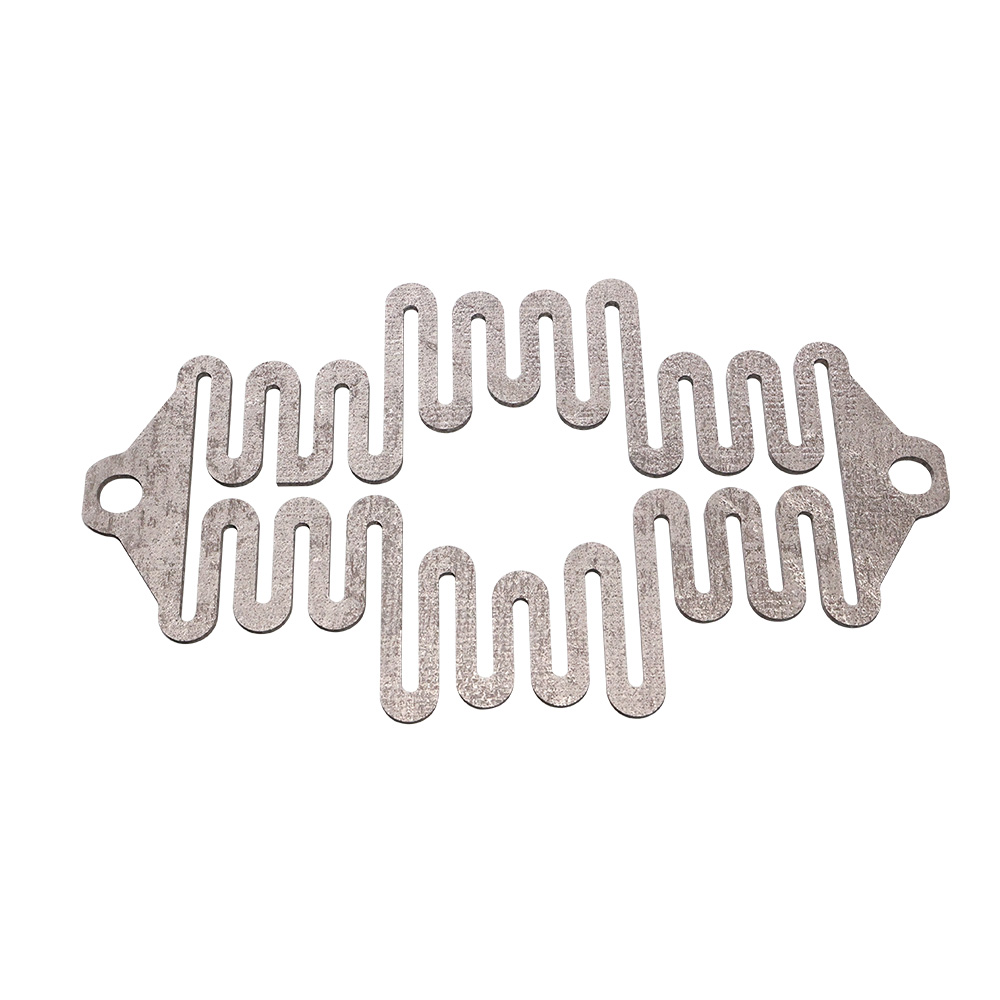

Single Crystal Furnace Heater: This product is used for the precise temperature regulation required in the crystallization of silicon, with temperature controls that ensure uniform heating.

Rigid Insulation Felt: A high-performance insulation material designed to withstand temperatures up to 2000°C. It offers excellent thermal insulation, reducing energy loss and improving system efficiency.

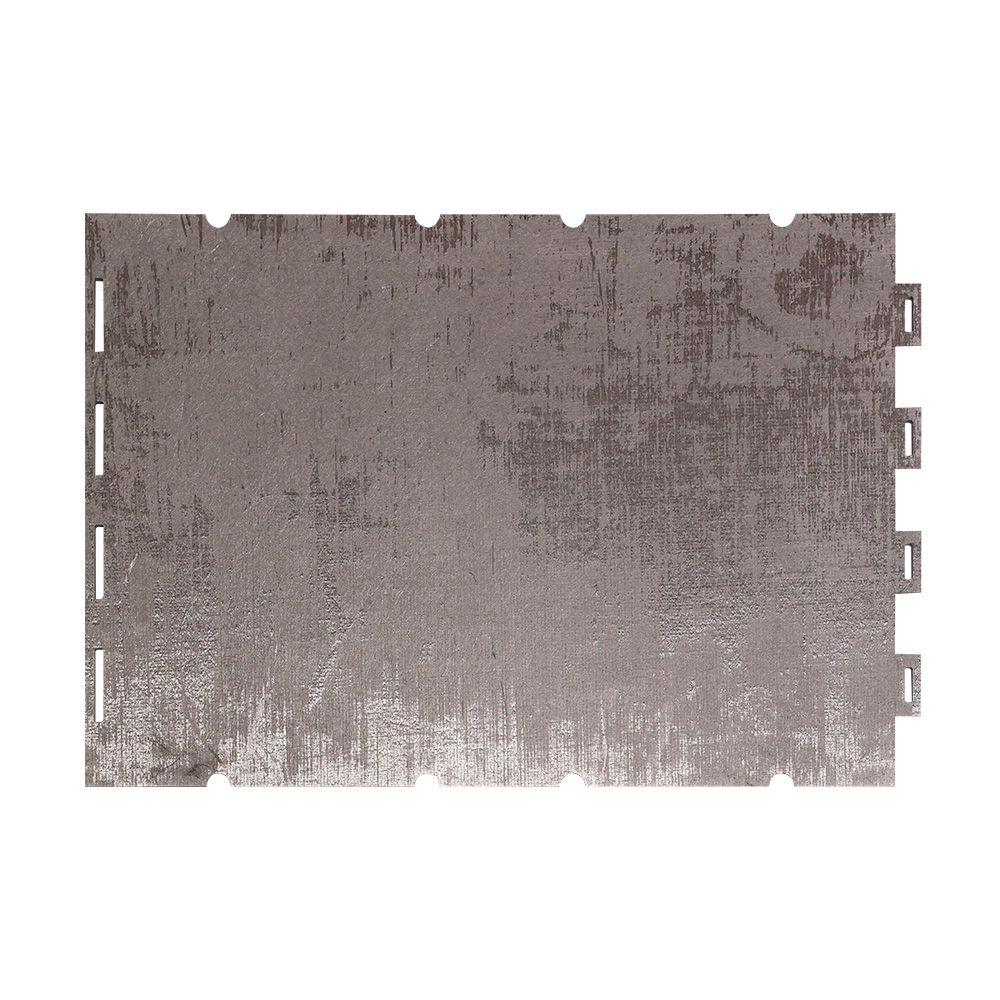

Graphitized Carbon Plate and Long Fiber Carbon Plate: These materials provide superior thermal conductivity and strength, with thickness options varying from 5mm to 30mm to cater to different thermal management needs.

Dehong’s carbon-carbon composite materials are engineered for ease of use and integration into solar PV thermal systems. Installation of Carbon Carbon Support Rings and Crucible Holders requires a professional understanding of high-temperature processes and should be done in accordance with Dehong’s provided guidelines to ensure safety and longevity of the products.

For products such as the Carbon Carbon Furnace Base Tray and Single Crystal Furnace Heaters, it is crucial to monitor operating temperatures regularly to avoid exceeding their maximum tolerance. Rigid Insulation Felt should be installed in a way that maximizes insulation coverage without obstructing heat flow, ensuring optimal thermal management. Care should be taken during handling to prevent any damage to the materials, as cracks or fractures can compromise their performance.

For maintenance, regular cleaning of products like the Graphitized Carbon Plate is recommended, using non-abrasive methods to avoid surface degradation. Inspect the Long Fiber Carbon Plate for any signs of wear or damage, especially after high-intensity usage, to ensure continued performance.

Dehong’s carbon-carbon composite materials are widely used in the solar photovoltaic thermal industry, particularly in the manufacturing of solar cells, modules, and panels. These materials are critical in the production of high-efficiency photovoltaic cells, where high temperatures and thermal cycling are common. The products also find use in other industries such as semiconductor manufacturing, aerospace, and energy production, where high-performance, heat-resistant materials are required.

The target customers for Dehong’s products in the solar PV thermal field include solar panel manufacturers, renewable energy companies, research institutions, and any other entities involved in the development and production of solar energy technologies. Dehong’s solutions are particularly beneficial for businesses that require reliable, long-lasting materials capable of withstanding extreme conditions during high-temperature manufacturing processes. Companies looking to improve the efficiency and longevity of their production equipment will find significant value in these advanced materials.